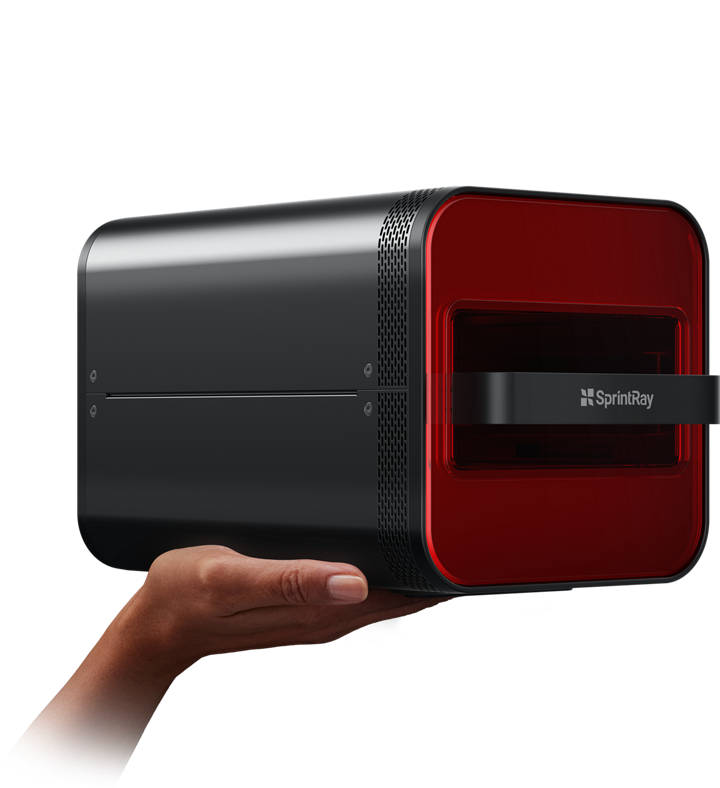

An all-new solution for 3D printing chairside restorations.

Discover effortless chairside excellence

The Straumann chairside workflow with Straumann Signature Midas by SprintRay makes single-visit restorations easier than ever. Benefit from a partnership that is set up to revolutionize dentistry and a solution that provides end-to-end workflow integration via Straumann AXS™ .

Digital Press Stereolithography (DPS)

Midas uses Digital Press Stereolithography, an innovative printing method that replaces the resin, tank and build platform with a resin capsule. This advancement allows Midas to print with highly-filled resins that are too viscous to use on a conventional 3D printer.

The Straumann Signature Midas is solely available through the Straumann Group.

One capsule, many possibilities

Midas accommodates up to three capsules at once. Print a range of dental retorations in less than 10 minutes.

Up to 3 crowns

Up to 6 inlays/onlays

The release of inlays and onlays is expected in autumn 2025.

Resin capsules not yet available in all markets. Contact your local organization for availability in your country.

Post-processing

After manual cleaning and drying, printed restorations will have to undergo a final curing cycle. The SprintRay NanoCure fits the fastest curing technology into a tiny form factor, making it easy to finish 3D printed parts in just a few minutes.

Brochures and videos

Looking for additional information? You'll find them in the Resource Center.

Straumann Signature Midas and resin capsules are manufactured by/for SprintRay Inc. , 2710 Media Center Drive, Suite 100, Los Angeles, CA 90065.